TCG-2001 Vacuum Suction Pressure Casting Machine

-Better casting quality through our TIP System, which eliminates pinholes

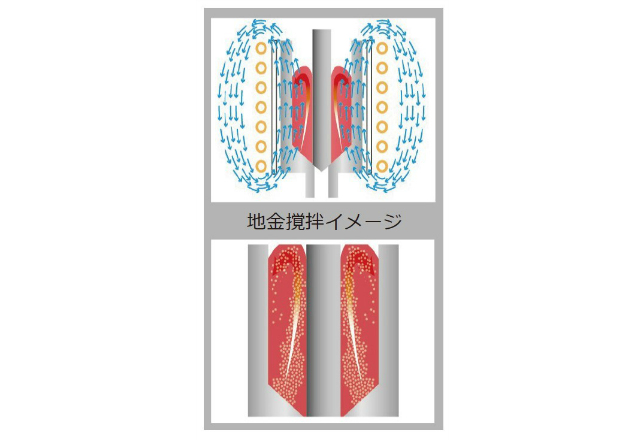

-Prevent separation of alloys through our original, high-quality oscillator

-Capable of doing many casting methods, includes program memory function

-Equipped with alarms from various kinds of sensors and with a log for analysis

-Separated chambers for complete control of gas used during casting process to reduce crucible wear and pinholes

-Casting is a simple process, but our detailed design allows for the highest quality of casting

| Power | AC200V 3ph 50/60Hz 6.5kVA |

|---|---|

| Size | 750(W) x 750(D) x 1150(H) mm |

| Weight | 300kg |

| Oscillator | 4.8kW 40kHz~50kHz |

| Range of thermometry | R-Sensor Below 1450℃ |

| Sensor position | Selectable at time of purchase : bottom of crucible or in stopper |

| Max pressurization | 0.2Mpa |

| Max volume | K24:2.6kg Ag:1.3kg |

| Mold sizes | Φ114 x 215(H)mm(MAX) |

| Type of flask | Straight flask/Flask with a flange |

| Method of seal | Straight flask, Investment/Flask with a flange, Graphite. (Select before usage) |

| Casting program | 20 patterns of setting can be programmed. |

| Casting methods | 1.Vacuum and pressure 2.Vacuum, suction, and pressure |

| Service power supply | 1.5KVA can be used for vacuum pump, chiller, and so on |

| Other | Compressed air 5kg (Constant) Cooling water (2.0L / min) |

Color touch panel

Sensor position

Chamber

Bullion stirring image