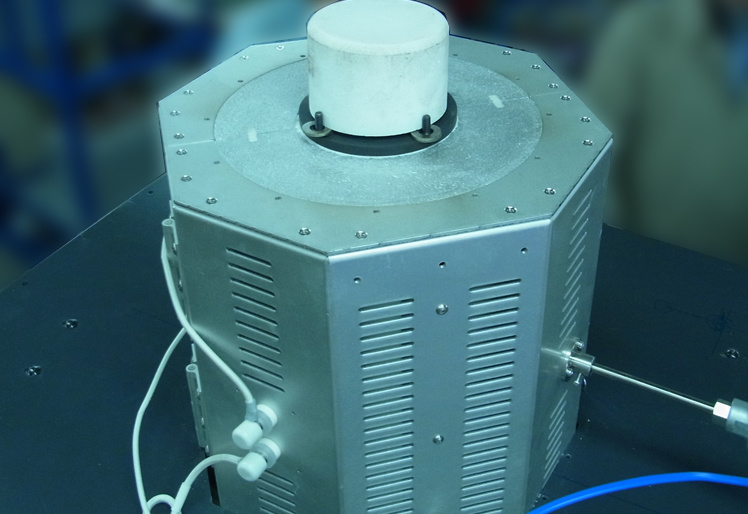

TFL-6400 Programmable Rotary Burnout Furnace

-High quality casting requires a high quality mold

-Expertly designed to allow for even heating of the mold so that wax is completed drained and burnt away

-Equipped with a muffle plate to prevent direct heat from causing unevenness

-Designed to minimize any unpleasant odors

| Power | AC200V 3ph 50/60Hz 13kVA |

|---|---|

| Size | 750(W) ×860(D) × 1870(H)mm *with after-burner |

| Weight | 315kg |

| Heater control | ON/OFF PID |

| Heater partition | Muffle(heat-resisting material) |

| Sensor | K(Inconel) |

| Table | Φ400 x 2 |

| Max mold numbers | Φ76.3mm:32pcs φ89.1mm:24pcs φ101.6mm:17pcs |

| Max height of mold | 200mm(MAX) |

| Safety functions | Over heating protection, Door sensor |

| After-burner | Syncronized with furnace |

| Program | 256steps / * Initial setting 16steps x16 patterns |

| Option | Data logger (program control) |

| Other | Compatible with industrial 4.0 |

Turn table

Foot switch

After burner

Door