TIC-40 Casting Machine for Titanium

-COMPACT & SEPARATE & LAYOUT FREE

TIC-40 is designed as a separate type with "caster", "power supply" and "vacuum pump" separated.

By separating them, you can freely arrange the layout regardless of the installation location.

The casting machine itself is compact and can be installed on a desk, allowing for efficient technical work.

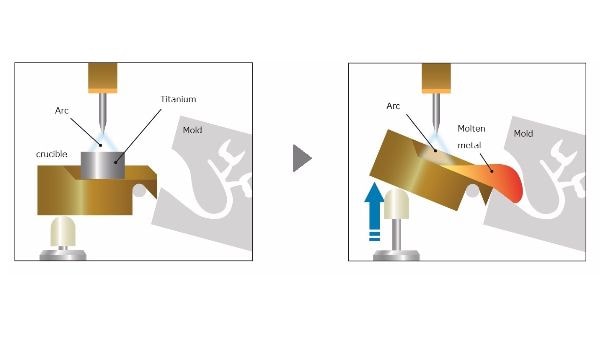

-Crucible tilting method that suppresses cooling of molten metal and enables highly accurate casting

By devising the layout of TIC-40, we have been able to bring the crucible and mold closer together, making it possible to suppress cooling of the molten metal. Furthermore, by continuing arc discharge during the pouring process, the efficiency of use of the riser is increased and the molten metal is distributed to every corner of the mold.

-Easy operation that anyone can use

Once you set the titanium weight in advance, all you have to do is press the start switch and it's fully automatic. There is no need to visually check the casting timing and no skill is required.

| Power | AC200V 1ph 50/60Hz 8.0kVA |

|---|---|

| Casting method | One-chamber pressurized casting method using argon gas * |

| Dissolution method | DC arc melting method in a reduced pressure argon atmosphere |

| Arc current | 200A constant |

| Dissolution ability | Titanium and titanium alloys up to 40g (14/20/25/30/40g) |

| Control mechanism | Fully automatic and manual control by program controller |

| Casting chamber capacity | Approximately 1.6L |

| Mold Sizes | Maximum diameter 90mm x height 60mm |

| Caster external dimensions | W200mm × H280mm × D350mm |

| Weight | Caster weight approx. 16kg / Power source weight approx. 19kg |

| Power supply external dimensions | W200mm × H315mm × D500mm |

| Pressure safety mechanism | Electric safety device: 1 (electromagnetic valve opens at 0.68MPa) Mechanical safety device: 2 (leak at approximately 0.7MPa) |

| *Argon gas is required to use this product. Please prepare your own argon gas. |